Your Custom Text Here

I would say we didn’t realize what we were getting into with this phase of the restoration, but we pretty much understood once we started there would be no going back. We were in 100%. We wanted to replace the roof that had been badly cobbled together when they extended the salon, and the owner before us cut a large hole to remove the engines after he had run Fifer aground and left her to languish and sink through a few tidal changes. The engines had to be rebuilt. That had never been repaired. The engines were rebuilt and left in a warehouse until we took the project on….and truth be told, that hole in the roof was used to crane the engines back into Fifer when we got to to that part of putting her back together. A hole in the water to throw money….and very large Gardener 6L3’s engines into.

As we spent more and more time observing How the structural elements had been settling underneath the pilothouse, it became obvious there was a large amount of rot that needed to be address in the mainbeam (that was holding up the the weight of the pilothouse) along with the carlings and beam clamps. We had removed the battery box that was installed in the engine room, nicely fiberglassed and painted. I had a difficult time with this because it looked great. LOL. It was one of the best looking parts of the engine room! We suspected that the space behind the very good-looking battery box held some ugly secrets. It did. The moisture was held against the side of the hull and rotted parts of the planks. The previous owner had let the rainwater pour into Fifer through the hole in the roof and decks that had not been maintained. The fresh water had rotted the deck beams and structural elements below. It was a big ol’ can o’ worms. Sometimes t’s just nice to pretend there isn’t anything wrong, right?

We decided, quite wisely I think, that instead of attempting to replaced the roof we should repair the structural problems before we took the roof on. Got to have a foundation before you can build on top of it. This wasn’t going to be a small task, and we decided on a plan to move forward. Money would have to be rustled up, and we needed to hire a competent shipwright. We hired a local guy who works on different yachts we know and came recommended.

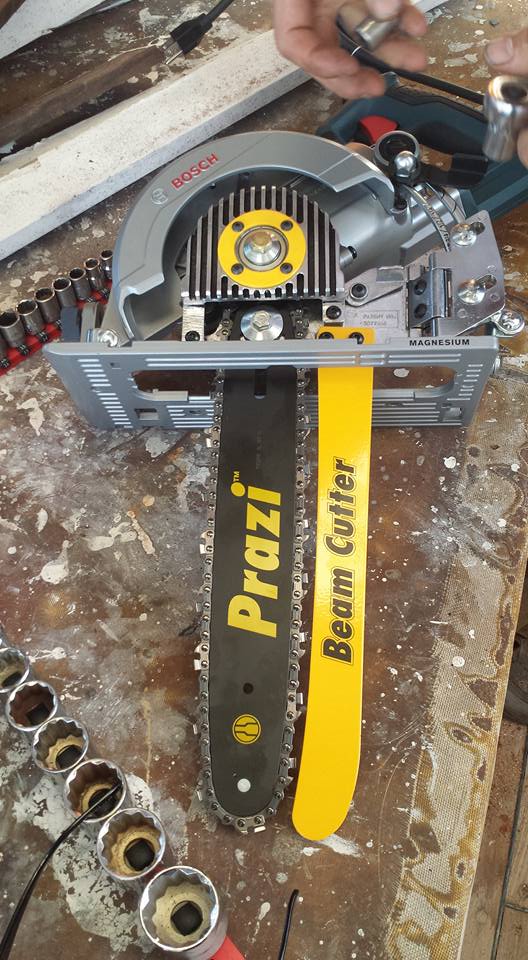

We had some curve balls thrown our way before we started but had already committed to the summer refit. We had someone rear-end us and both of us were injured, but we soldiered on in spite of some pain and discomfort. We rented a boathouse in our marina so we could keep Fifer undercover while we were working, and things took off in early July. The “tearing the rot out” phase went on WAY too long. It was terrifying hearing the sound of a Sawz-All ripping through the mainbeam and other rotten parts. As we got a better idea of what we were looking at, the extent of how far we were going to have to go to completely stabilize the structure under the pilothouse. Over the years the previous owners had done all kinds of things to cover up the fact that the structure was rotting and dropping. Things were failing to line up properly because the pilohouse had dropped 3/4 of an inch, and putting a new roof on was out of the question until we fixed everything.

We also decided while we had everything torn our that we would replace the planks in the engine room that were well above the waterline that were rotted. we had about four that were of concern to us. Over the years that had shorted many of the planks in pursuit of quick repairs, many sections were only a couple of feet long instead of full-length (up to 20 ft+ in many cases) as they were supposed to be. We worked throughout the summer completing the necessary repairs and starting the removal of the old roof.

To be continued….

I would say we didn’t realize what we were getting into with this phase of the restoration, but we pretty much understood once we started there would be no going back. We were in 100%. We wanted to replace the roof that had been badly cobbled together when they extended the salon, and the owner before us cut a large hole to remove the engines after he had run Fifer aground and left her to languish and sink through a few tidal changes. The engines had to be rebuilt. That had never been repaired. The engines were rebuilt and left in a warehouse until we took the project on….and truth be told, that hole in the roof was used to crane the engines back into Fifer when we got to to that part of putting her back together. A hole in the water to throw money….and very large Gardener 6L3’s engines into.

As we spent more and more time observing How the structural elements had been settling underneath the pilothouse, it became obvious there was a large amount of rot that needed to be address in the mainbeam (that was holding up the the weight of the pilothouse) along with the carlings and beam clamps. We had removed the battery box that was installed in the engine room, nicely fiberglassed and painted. I had a difficult time with this because it looked great. LOL. It was one of the best looking parts of the engine room! We suspected that the space behind the very good-looking battery box held some ugly secrets. It did. The moisture was held against the side of the hull and rotted parts of the planks. The previous owner had let the rainwater pour into Fifer through the hole in the roof and decks that had not been maintained. The fresh water had rotted the deck beams and structural elements below. It was a big ol’ can o’ worms. Sometimes t’s just nice to pretend there isn’t anything wrong, right?

We decided, quite wisely I think, that instead of attempting to replaced the roof we should repair the structural problems before we took the roof on. Got to have a foundation before you can build on top of it. This wasn’t going to be a small task, and we decided on a plan to move forward. Money would have to be rustled up, and we needed to hire a competent shipwright. We hired a local guy who works on different yachts we know and came recommended.

We had some curve balls thrown our way before we started but had already committed to the summer refit. We had someone rear-end us and both of us were injured, but we soldiered on in spite of some pain and discomfort. We rented a boathouse in our marina so we could keep Fifer undercover while we were working, and things took off in early July. The “tearing the rot out” phase went on WAY too long. It was terrifying hearing the sound of a Sawz-All ripping through the mainbeam and other rotten parts. As we got a better idea of what we were looking at, the extent of how far we were going to have to go to completely stabilize the structure under the pilothouse. Over the years the previous owners had done all kinds of things to cover up the fact that the structure was rotting and dropping. Things were failing to line up properly because the pilohouse had dropped 3/4 of an inch, and putting a new roof on was out of the question until we fixed everything.

We also decided while we had everything torn our that we would replace the planks in the engine room that were well above the waterline that were rotted. we had about four that were of concern to us. Over the years that had shorted many of the planks in pursuit of quick repairs, many sections were only a couple of feet long instead of full-length (up to 20 ft+ in many cases) as they were supposed to be. We worked throughout the summer completing the necessary repairs and starting the removal of the old roof.

To be continued….